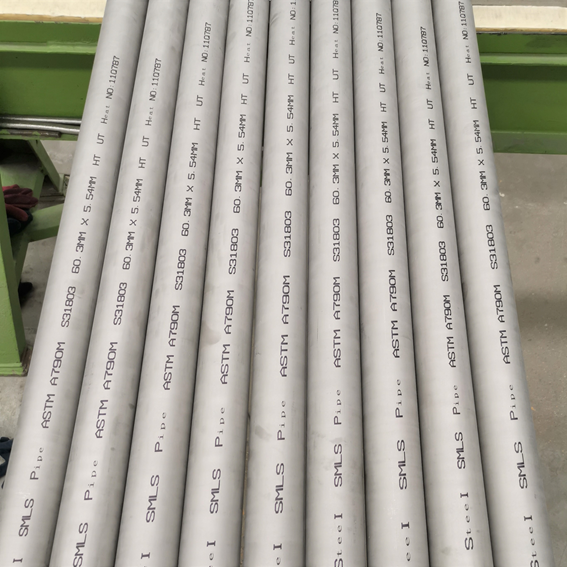

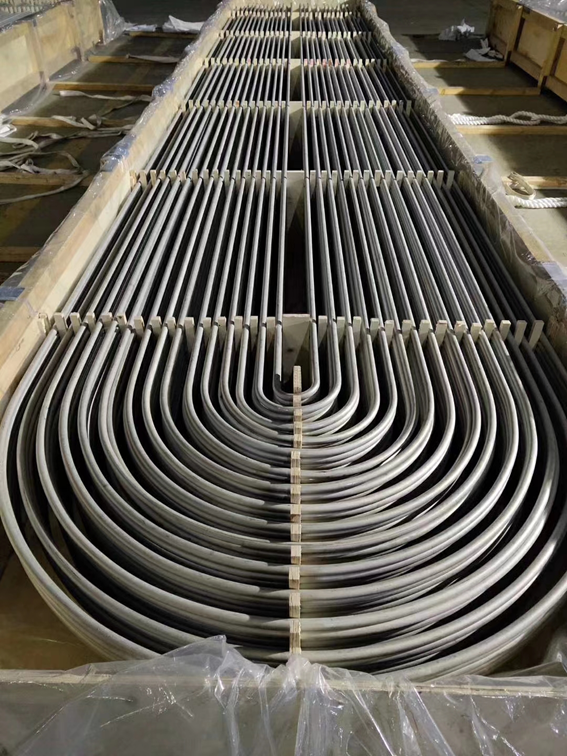

Heat exchanger chemical equipment s22053 stainless steel heat exchange tube

S31803 / s22053 stainless steel heat exchange tube 2205 duplex stainless steel fluid tube 2205 stainless steel boiler tube 022cr23ni5mo3n stainless steel tube S32205 duplex stainless steel seamless tube for heat exchanger chemical equipment

Duplex stainless steel has been widely used, of which 2205 duplex stainless steel is also the most widely used. Corrosion resistance of dual phase steel 1. Pitting corrosion resistance the pitting corrosion resistance of steel depends on the elements of chromium, molybdenum and nitrogen in the steel. The pitting index of several dual phase stainless steels and austenitic stainless steels is compared. PrEN value is generally used to predict the performance of steel in chloride environment. The pitting corrosion resistance of 2205 steel in chlorine environment is better than 18-5Mo section steel and 316L stainless steel. The relationship between CPT value and chloride ion content at 300mV potential shows that 2205 duplex stainless steel is better than 2304 duplex stainless steel.

The crevice corrosion resistance of 2205 steel is equivalent to that of 316L austenitic stainless steel, while the stress corrosion resistance. During the stress corrosion process of dual phase stainless steel, whether ferrite phase or austenitic phase, one of them must be relative to the other, which plays a role of polarization protection or mechanical barrier in the propagation of stress corrosion cracks, Thus, the possibility of crack development is prevented. In addition, the orientation difference of the crystal planes of the two phases makes the crack in the process of propagation change the direction frequently, which greatly prolongs the propagation period of stress corrosion crack. 2205 steel has good chloride stress corrosion resistance, even in both chloride and H2S.

Intergranular corrosion resistance:

2205 steel contains nitrogen and still retains a large amount of austenite phase after high temperature heating (at 1250 ℃) γ The phase is 30% ~ 40%), and when the welded high temperature heat affected zone (HTHAZ) is cooled, it will quickly change from ferrite phase to austenite phase along the ferrite phase grain boundary. This two-phase structure reduces the intergranular corrosion tendency of the steel and makes 2205 steel have good intergranular corrosion resistance.