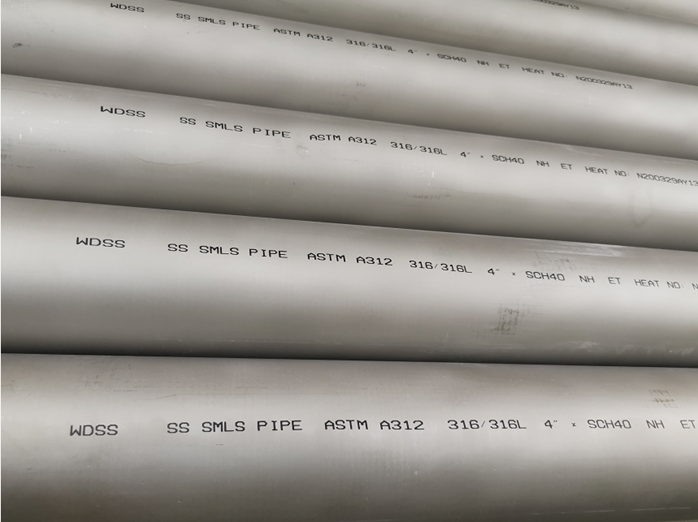

Petrochemical engineering equipment 316/316L stainless steel pipe

316L stainless steel pipe for heat exchanger boiler 316L stainless steel seamless pipe is widely used in chemical projects. 316L is an austenitic stainless steel based on molybdenum. Compared with conventional chromium nickel austenitic such as 304 alloy, this steel has better resistance to general corrosion, pitting corrosion and crack corrosion. This alloy has higher ductility, stress corrosion resistance, compressive strength and high temperature resistance.

316L attributes:

Corrosion resistance of 316L steel: 316L is widely used in the chemical industry because of its excellent corrosion resistance. It is also a derivative steel of 18-8 austenitic stainless steel, with 2 ~ 3% Mo added. On the basis of 316L, many steel grades are also derived. For example, 316Ti is derived after adding a small amount of Ti, 316N is derived after adding a small amount of N, and 317L is derived by increasing the content of Ni and mo.

The American standard stipulates that the Ni content of 316L is 10 ~ 14%, and the Japanese standard stipulates that the Ni content of 316L is 12 ~ 15%. According to the minimum standard, there is a difference of 2% in Ni content between American Standard and Japanese standard, which is reflected in the price. The Mo content of 316L makes the steel have excellent pitting corrosion resistance and can be safely applied to the environment containing Cl - and other halogen ions. Since 316L is mainly used for its chemical properties, steel mills have slightly lower requirements for surface inspection of 316L (compared with 304), and customers with higher surface requirements should strengthen surface inspection.

Corrosion resistance general corrosion

Compared with 18-8 stainless steel, 316L and 317L have better corrosion resistance in atmospheric environment and other mild environments. Generally speaking, media that do not corrode 18-8 stainless steel will not corrode the grade containing molybdenum. The only exception is high oxidizing acids, such as nitric acid. Stainless steel containing molybdenum has weak corrosion resistance to this acid. In sulfuric acid solution, 316L and 317L have better corrosion resistance than other chromium nickel types. Both grades have good corrosion resistance to high concentration solutions at temperatures up to 120 ° f (38 ° C). Of course, testing during use is essential because operating conditions and acidic contaminants may seriously affect the corrosion rate. When concentrating sulfur-containing gas, these two grades have better corrosion resistance than other types of stainless steel. However, in such applications, the effect of acid concentration on corrosion rate is quite large, which should be carefully considered. Molybdenum containing stainless steel 316L and 317L have certain corrosion resistance to other environments. The steel shows superior corrosion resistance in boiling 20% phosphoric acid solution. They are also widely used in the treatment of thermal organic acids and fatty acids. Stainless steel containing molybdenum is usually used in the manufacture and treatment of food and pharmaceutical products, because metal pollution should be minimized. Generally speaking, under the same environmental conditions, 316 can be regarded as equivalent to 317. However, the exception is in the environment that can cause intergranular corrosion in the welding heat affected zone. In such media, 316L and 317L are more often selected because of their low carbon content and improved intergranular corrosion resistance

Compared with 18-8 stainless steel, 316L and 317L have better corrosion resistance in atmospheric environment and other mild environments. Generally speaking, media that do not corrode 18-8 stainless steel will not corrode the grade containing molybdenum. The only exception is high oxidizing acids, such as nitric acid. Stainless steel containing molybdenum has weak corrosion resistance to this acid. In sulfuric acid solution, 316L and 317L have better corrosion resistance than other chromium nickel types. Both grades have good corrosion resistance to high concentration solutions at temperatures up to 120 ° f (38 ° C). Of course, testing during use is essential because operating conditions and acidic contaminants may seriously affect the corrosion rate. When concentrating sulfur-containing gas, these two grades have better corrosion resistance than other types of stainless steel. However, in such applications, the effect of acid concentration on corrosion rate is quite large, which should be carefully considered. Molybdenum containing stainless steel 316L and 317L have certain corrosion resistance to other environments. The steel shows superior corrosion resistance in boiling 20% phosphoric acid solution. They are also widely used in the treatment of thermal organic acids and fatty acids. Stainless steel containing molybdenum is usually used in the manufacture and treatment of food and pharmaceutical products, because metal pollution should be minimized. Generally speaking, under the same environmental conditions, 316 can be regarded as equivalent to 317. However, the exception is in the environment that can cause intergranular corrosion in the welding heat affected zone. In such media, 316L and 317L are more often selected because of their low carbon content and improved intergranular corrosion resistance