Intergranular corrosion test of stainless steel pipe

What is the qualified index of intergranular corrosion inspection of stainless steel ?

-What is the qualified index of intergranular corrosion inspection of stainless steel?

ss304 pipe 316l stainless steel pipe, 904 stainless steel tube

The inspection qualification indexes of cold drawn (cold rolled) stainless steel pipes, stainless steel pipe fittings and stainless steel flanges used for stainless steel containers shall be the same as those of stainless steel containers.

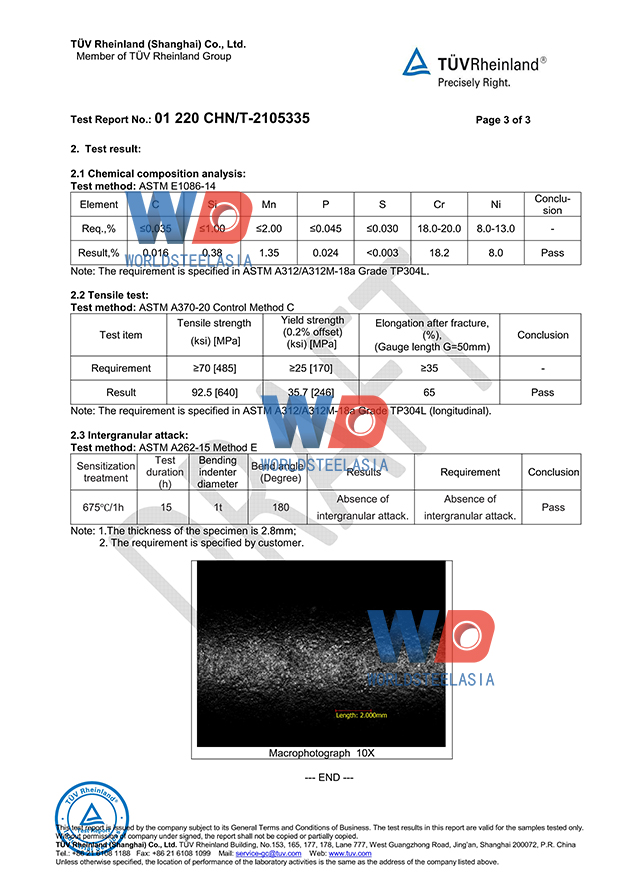

2.10% oxalic acid etching test shall be conducted according to the provisions of ASTM a262 and other corresponding standards, and compared with the standard etching organization chart to judge whether it passes. If it passes, it indicates that the selected hot acid test method is qualified; If it fails, it indicates that the screened hot acid test method must be tested to determine whether it is qualified. When determining the 10% oxalic acid method as the independent inspection method, whether the oxalic acid method passes or not is taken as the basis for inspecting whether the corrosion performance of 304 stainless steel pipe is qualified.

3. Sulfuric acid copper sulfate method shall be in accordance with the provisions of ASTM a262 method a or method B and other corresponding standards, and the bending method supplemented by metallographic method shall be used to judge that there is no intergranular corrosion crack on the outer surface of the bending sample as the qualified index. 316 and 316L s31603 materials are corrosion resistant.

The application of duplex steel materials S31803 and S32750 slms pipe will be introduced later

4. Sulfuric acid ferric sulfate method shall be determined by corrosion rate or bending method (the tube sample can be flattened method) according to the provisions of ASTM a262, method C in ISO 3651-2:1998 (E) and other corresponding standards. When judging by the corrosion rate, it is generally regarded as qualified if the corrosion rate is not higher than 1.2 mm / A, and the design is allowed to specify other qualified indicators of corrosion rate according to specific conditions. When judged by bending method or flattening method, it is qualified if there is no intergranular corrosion crack on the outer surface of the sample.

904L has good corrosion resistance in terms of seawater corrosion resistance, that is, UNS 8904 stainless steel seamless pipe

5. The nitric acid method shall be judged according to the average corrosion rate of 5 cycles or the maximum corrosion rate of 3 cycles according to the provisions of ASTM a262, or according to the corrosion rate of each and all cycles of 5 cycles (which can be changed by agreement) according to the provisions of ISO 3651-1:1998 (E). Generally, the corrosion rate not exceeding 0.6 mm / A is regarded as the qualified index, and when the requirements are high, it can also be regarded as not exceeding 0.46 mm / A or 0.30 mm / A. When it is a welded joint sample, the fusion line shall be qualified without knife corrosion.

The quality control of worldsteelasia is very good. It is tested in full accordance with the standard. All testing performance is qualified. Our stainless steel pipeline products have been highly recognized by customers in the United States, Canada and South America.

6. If one of the parallel samples in the same test piece is unqualified, it is allowed to take two samples again to repeat the test. If all samples are qualified, they are qualified. One of them is unqualified

If you want to know more about stainless steel pipe products, please contact me. Remember that we are one of the best stainless steel suppliers in China