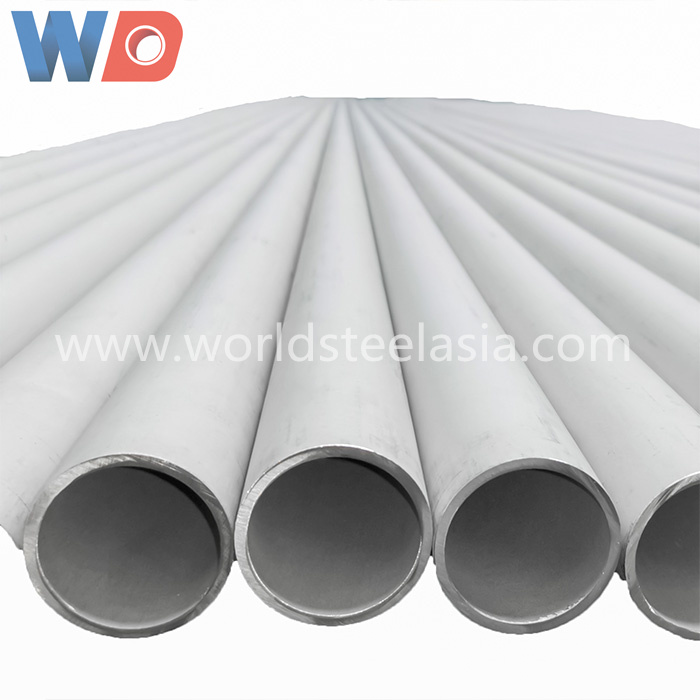

stainless steel piping

-

Seamless Stainless Steel Tube

Seamless Stainless Steel Tube Seamless Stainless Steel Tube, as the name suggests, is a Tube without a seam or a weld joint. Seamless Tubes are thought to be able to withstand higher pressure, higher temperatures, higher mechanical stress and a corrosive atmosphere. Manufacture of Seamless Stainless Steel Tube Seamless Stainless Steel Tube are manufactured using a variety of different methods, cold rolling or cold drawing. The method used is dependent on what diameter, or what ratio of the diameter to the thickness of the wall, is required by the application it is being put into. Generally speaking, Seamless Stainless Steel Tube is made by raw steel first being cast into a more workable format – a hot solid billet. Seamless Stainless Steel Tube is then ‘stretched’ and then pushed or pulled over a moulding form. This results in the creation of a hollow Tube. This hollow Tube is then ‘extruded’ and forced through a die and mandrel in order to achieve the Seamless Stainless Steel Tube desired diameters of the inside and outside walls. To guarantee Seamless Stainless Steel Tube meets certain standards, it has to be heat-treated in specific ways to ensure Seamless Stainless Steel Tube the metallurgic properties are in accordance with the necessary requirements. This ensures extremely high quality and durability for our clients. We work Raw materail manufactures with BAOSTEEL, TISCO, YONGXIN, WASIN, TSINGSHAN we can be confident in the products which we supply and know we can rely on their quality and performance. Everything we supply is manufactured in accordance with the American Society for Testing & Materials (ASTM) Standards and the American Society of Mechanical Engineers (ASME) The dimensional standard of the Seamless Stainless Steel Tubes we supply are in accordance with the American National Standards Institute (ANSI): ANSI B36.19, ANSI B36.10 , other Size can be customized to customer requirements chan

Email Details