Research on Large-Diameter Austenitic Stainless Steel Seamless Steel Tubes

1. The process flow of large-diameter austenitic stainless steel seamless steel tube: Preparation of billet -> Heating in a furnace on a trolley -> Rolling -> Online water cooling -> Solution treatment (solution treatment + stabilization treatment) -> Straightening -> Non-destructive testing -> Pickling, Passivation -> Inspection -> Packaging.

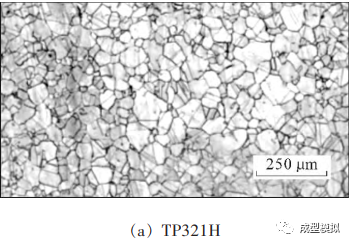

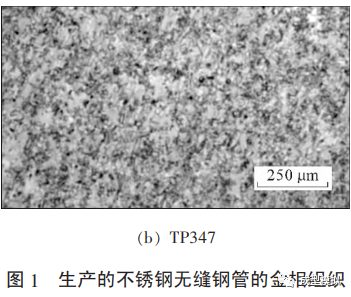

2. The pipe blank is manufactured using the method of "electric furnace (or converter) + external refining + vacuum degassing + forging," with a forging ratio of 3.0-3.5. When customers require a grain size of 5-7 levels for austenitic stainless steel pipes (higher than the requirement of level 7 or coarser in ASME SA312/SA 312M-2010 "Seamless and Welded Austenitic Stainless Steel Pipes" standard), the grain size of the forged austenitic stainless steel round tube blank should be limited to 2.5-4.0 levels.

3. Stainless steel has a high coefficient of low-temperature thermal expansion. If the heating speed is too fast, there will be a large temperature difference between the inside and outside of the pipe blank, which can easily lead to cracking. Therefore, when heating below 600°C, the heating rate should be strictly controlled. In actual production, a rate of 150-300°C/h is recommended. At the same time, stainless steel has high deformation resistance at high temperatures. If the heating temperature is too low, it cannot ensure the subsequent piercing temperature, resulting in failure to bite and roll sticking during the rolling process. If the heating temperature is too high or the dwell time at high temperature is too long, a large amount of delta ferrite will form, affecting the thermal processing performance. Therefore, the heating temperature should be controlled at 1200-1250°C.

4. When austenitic stainless steel is rolled in the temperature range of 1000-1250°C, it exhibits good plasticity compared to low-temperature rolling, and the deformation resistance increases sharply with decreasing rolling temperature. The final rolling temperature should generally not be lower than 950°C, and the maximum relative reduction should not exceed 20%.

5. In order to obtain a single-phase austenitic structure, ensure the maximum corrosion resistance and restore maximum toughness of the steel tube, austenitic stainless steel must undergo solution treatment. The solution treatment temperature should not be too high or too low, and the number of heat treatments should not exceed two. If the solution temperature is too low, carbides cannot fully dissolve in the solid solution. On the other hand, high temperature and repeated heat treatment will cause grain growth, reducing the toughness of the steel tube and increasing the tendency for intergranular corrosion. The solution treatment temperature for TP304, TP316 specified in ASME SA312/SA 312M should not be lower than 1040°C, and for TP321, TP347 should not be lower than 1050°C. Based on the capabilities of the company's heat treatment equipment, the solution treatment temperature is set at 1050-1080°C.