Research on the Smelting Technology of Low [O] Content and High-Purity Duplex Steel and supler duplex steel

Taking 2507 and 2205 as representative steel grades, this study explores the key elements of the smelting technology of duplex stainless steel from the following four aspects:

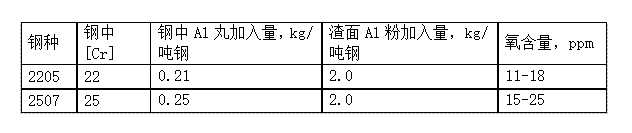

1.Adopting Al deoxidation, ensuring the premise of deoxidation, and preventing the formation of AlN. The deoxidation process of "AOD furnace with aluminum pellets + slag surface with aluminum powder" is used. The final aluminum content is 0.012% to 0.018%, and the oxygen content is reduced to 10 ppm to 30 ppm.

Table 1: Influence of aluminum addition on oxygen content of different duplex stainless steels

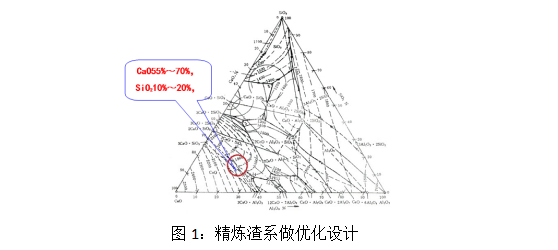

2.Optimization of LF refining slag system

Obtain optimized high-aluminum alkaline refining slag composition: CaO 55% to 70%, SiO2 10% to 20%, Al2O3 15% to 20%; high alkalinity, low melting point, deep desulfurization, and adsorption of Al2O3-type inclusions.

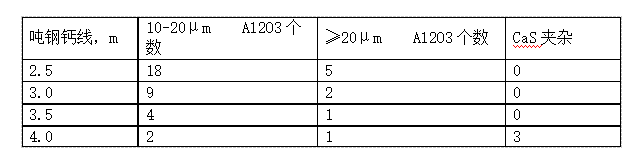

3.Optimization of calcium treatment process

The feeding amount of the calcium line is 3.5 m/ton of steel, which can effectively modify Al2O3 inclusions: ensure that the low-melting 12CaO·7Al2O3 inclusions generated are in liquid state and do not generate solid CaS inclusions, as shown in Table 2.

Table 2: Comparison of the number and size of Al2O3 inclusions in the test with different calcium line feeding amounts per ton of steel

4.Argon soft blowing

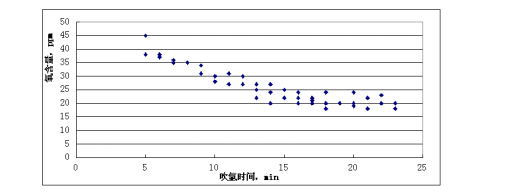

With the extension of the soft blowing argon time, the oxygen content in the steel decreases, and the decreasing trend slows down when the soft blowing argon time exceeds 15 minutes. When treating duplex stainless steel, the soft blowing argon time should be controlled within 15-25 minutes.

Image 2: Soft blowing argon time

duplex steel pipe fittings flange bar plate sheet coil also can do grade UNS S31803 / 2205 , S32750 / 2507

made in china