Why should the impact test be notched for stainless steel pipe

Grade 304L 321 316L Why should the impact test be notched stainless steel pipe

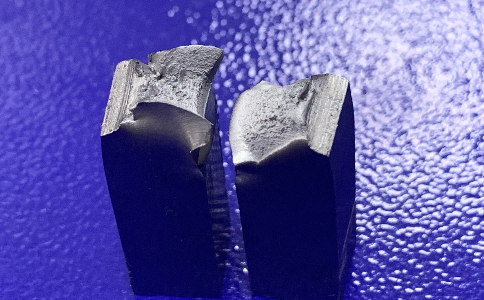

Metal impact test is a test used to determine the notch resistance sensitivity (toughness) of metal materials. Prepare a metal sample with a certain shape and size to make it have a U-shaped notch or V-shaped notch. It is in the state of simply supported beam on the Charpy impact testing machine. Make an impact with the pendulum lifted by the testing machine to make the sample break along the notch. Calculate the absorption work of the sample by the difference of the re lifting height of the pendulum when breaking, that is, Aku and Akv The impact test can be carried out at different temperatures. Large absorption work value (joule) indicates that the material has good toughness and is not sensitive to notch or other stress concentration in the structure. For the materials of important structures, in recent years, V-notch specimens which can better reflect the notch effect are tend to be used for impact test. Our stainless steel seamless pipe can do low temperature impact test at - 190 ℃.

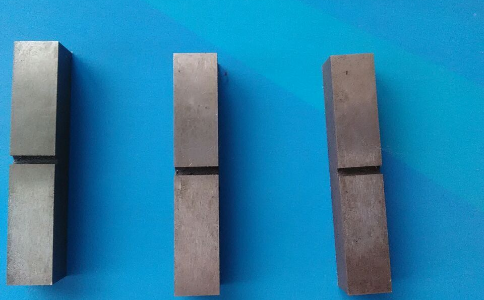

stainless steel seamless pipe

1. Different impact absorption energy:

The impact absorption function measured by Charpy V-notch is expressed by Akv.

The impact absorption function measured by Charpy u-notch specimen is expressed by Aku.

2. Different gap sizes:

Sharp Charpy V-notch. The Charpy u-notch is gentle.

3. The causes of impact energy are different:

In the impact test of U-shaped specimen, most of its impact energy is consumed in the formation of crack.

For V-notch specimens, most of the impact energy is consumed by crack propagation.

Charpy impact test to determine the notch resistance sensitivity of metal materials. Prepare a metal sample with a certain shape and size, make it have a U-shaped notch or V-shaped notch, and be in the state of simply supported beam on the Charpy impact testing machine. Make an impact with the pendulum lifted by the testing machine to make the sample break along the notch. Calculate the absorption work of the sample with the height difference of the pendulum raised again when breaking, that is, Aku and Akv.

The impact test can be carried out at different temperatures. Large absorption work value indicates that the material has good toughness and is not sensitive to notch or other stress concentration in the structure. For the materials of important structures, in recent years, V-notch specimens which can better reflect the notch effect are tend to be used for impact test.

Impact test of seamless stainless steel pipe at room temperature or low temperature

Compared with the same material, the impact toughness of V-notch is much lower than that of u-notch. The V-shaped stress is relatively concentrated, and it becomes more sensitive when the sample is impacted. As for why the new standard mostly adopts V-shaped samples, in addition to the above reasons, the improvement of sample processing technology is also one of them. Now there is a special broaching machine for processing V-shaped gaps, and the processing accuracy can meet the specified requirements. Generally speaking, metal materials with high plastic toughness (Akv greater than 20j) and low temperature toughness requirements shall adopt V-type; Medium plastic toughness, U-shaped; If the plastic toughness is poor, no notch shall be opened