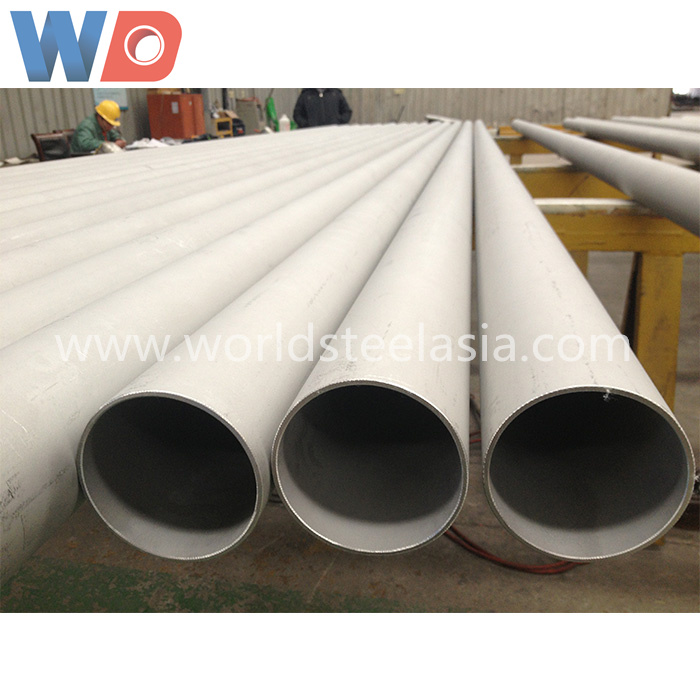

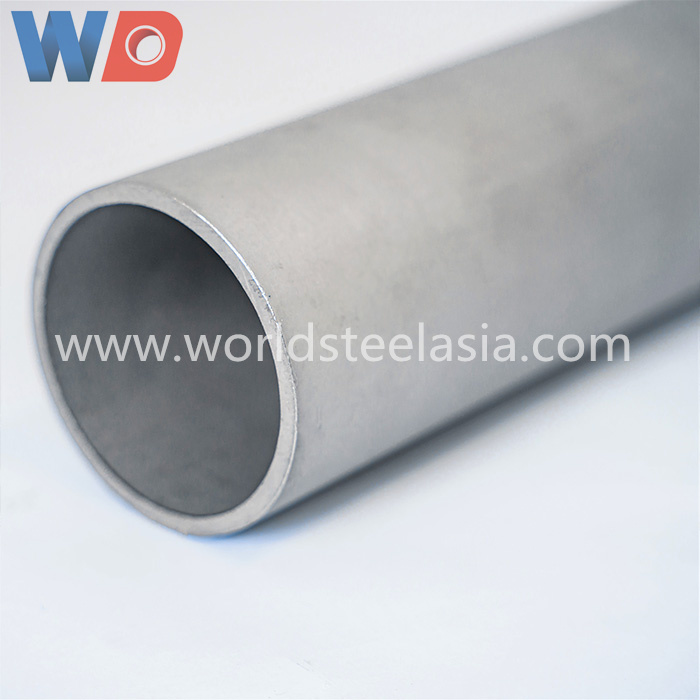

S31803 Duplex Steel Seamless Pipe

#DUPLEX STEEL SEAMLESS PIPING MATERIALS

Duplex stainless steel is a very useful metal that is used the world over. It gets its name from the fact that it consists of two different grades of metal. S31803 Duplex Steel Seamless Pipe has better corrosion resistance and better mechanical properties

Duplex steel seamless pipe is a Fe-Ni-Cr alloy that has a two-phase ferritic-austenitic stainless-steel microstructure when it is at room temperature.

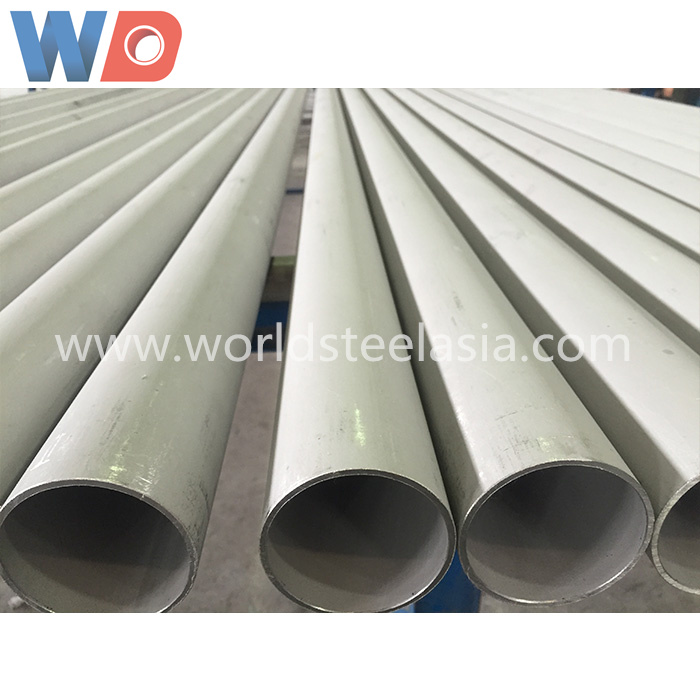

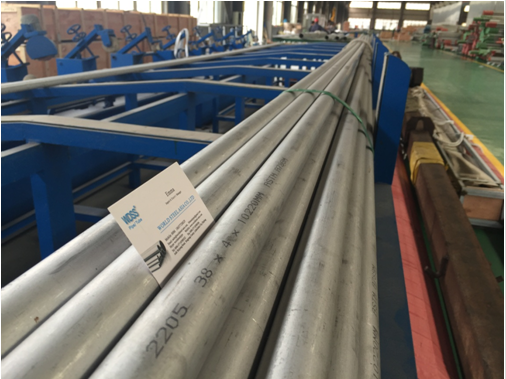

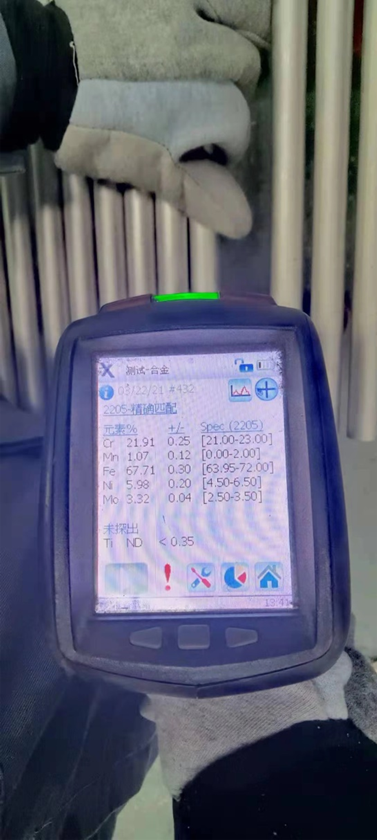

Duplex Stainless steel pipe are characterised by high chromium (19–28%) and molybdenum (up to 5%) and lower nickel contents than austenitic stainless steels. The most used duplex stainless steel are the 2205 seamless pipe (22% Chromium, 5% Nickel) and the 2507 (25% Chromium, 7% Nickel); 2507 is known as “super duplex steel” due to its higher resistance to corrosion.

The advantage of combining ferritic and austenitic grades is that the resultant metal has a metallurgical structure that consists of two phases and therefore benefits from the properties of both microstructures.

These properties make duplex steel highly sought after in heavy industries, like oil and gas nuclear and chemical processing.

ChongQing World Steel Co Advantages of seamless Duplex steel pipe S31803 S32750 S2205 etc

Duplex stainless steel seamless pipe has an array of various benefits such as:

Strength: #Duplex stainless steel pipe have approximately double the strength of regular austenitic or ferritic stainless steel.

Toughness and ductility:Duplex stainless steel exceed the toughness and ductility of ferritic grades although they are not as touch as austenitic grades.

Corrosion resistance: As with all stainless steel pipe, corrosion resistance depends mostly on the composition of the stainless steel, with chromium, molybdenum and nitrogen content being the most important. Duplex stainless steels are extremely corrosion resistant and even in chloride and sulphide environments, duplex stainless steels exhibit very high resistance to stress corrosion cracking . duplex steel pipe is a type of corrosion duplex steel pipe takes place when a particular set of factors are present: Tensile stress, corrosive environment and a sufficiently high temperature.

CHONGQING WORLD STEEL CO.,LTD | |||||||||||

Grade | UNS | Composition, %B | |||||||||

Carbon | Manga- nese | Phos- phorus | Sulfur | Silicon | Chrom- ium | Nickel | Molyb- denum | Nitro- genC | Copper | ||

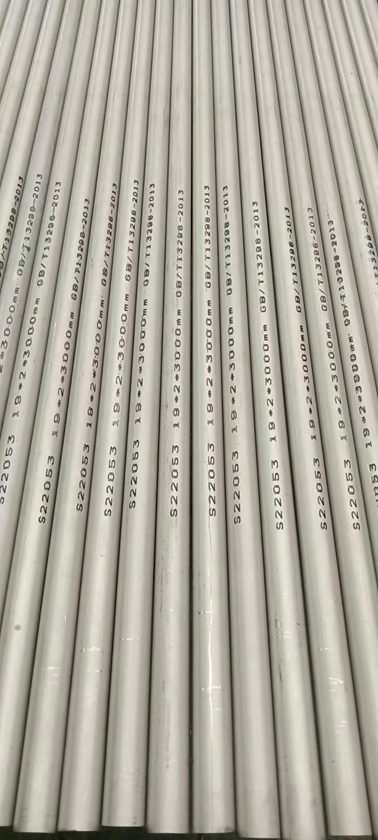

S31803 | S31803 | 0.030 | 2.00 | 0.030 | 0.02 | 1.00 | 21.0 – 23.0 | 4.5.0 – 6.5 | 2.5 – 3.5 | 0.08 – 0.20 | . . . |

2205 | S32205 | 0.030 | 2.00 | 0.030 | 0.02 | 1.00 | 22.0 – 24.0 | 4.5.0 – 6.5 | 3.0 – 3.5 | 0.14 – 0.20 | . . . |

2507 | S32750 | 0.030 | 1.20 | 0.035 | 0.020 | 0.80 | 24 – 28.0 | 6.0 – 8.0 | 3.0 – 5.0 | 0.24 – 0.32 | 0.50 |

Mill Test Certificate is supplied with shipment.

If needed, a Third Party Inspection is acceptable.

Duplex stainless steel can be subdivided into:

The first type is low alloy type, representing the brand UNS s32304 (23cr-4ni-0.1n). The steel does not contain molybdenum, and the prEN value is 24-25. It can be used instead of AISI304 or 316 in terms of stress corrosion resistance.

The second type belongs to medium alloy type. The representative brand is UNS S31803 (22cr-5ni-3mo-0.15n), and the prEN value is 32-33. Its corrosion resistance is between AISI 316L and 6% Mo + n austenitic stainless steel.

The third type belongs to high alloy type, which generally contains 25% Cr, molybdenum and nitrogen, and some also contain copper and tungsten. The standard brand is unss32550 (25cr-6ni-3mo-2cu-0.2n), and the prEN value is 38-39. The corrosion resistance of this kind of steel is higher than that of duplex stainless steel with 22% CR.

The fourth type is super duplex stainless steel, which contains high molybdenum and nitrogen. The standard brand is UNS S32750 (25cr-7ni-3.7mo-0.3n). Some also contain tungsten and copper. The prEN value is greater than 40. It can be applied to harsh medium conditions. It has good corrosion resistance and mechanical properties, which is comparable to super austenitic stainless steel.

Product application

It is used for heat exchangers, chillers and devices resistant to seawater, high temperature and concentrated nitric acid in oil refining, chemical fertilizer, papermaking, petroleum and chemical industry.

Product features

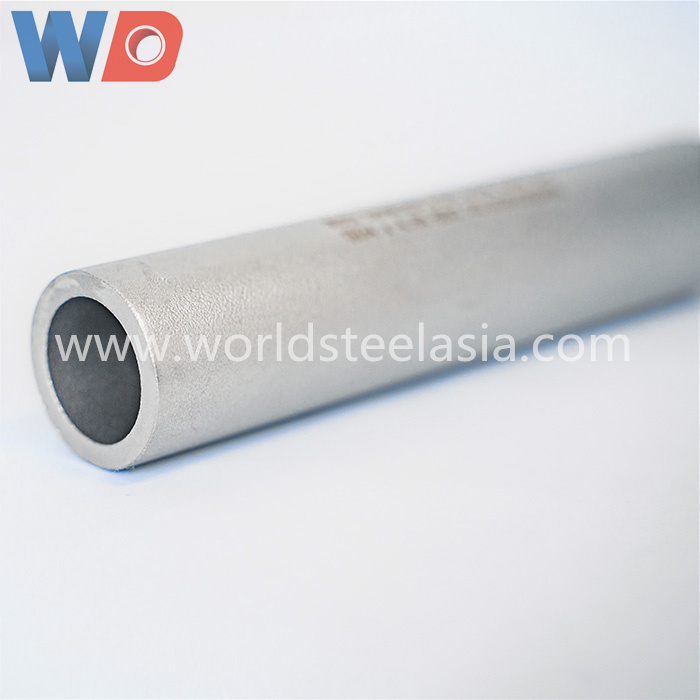

1. Corrosion resistance

Excellent overall corrosion resistance and local corrosion resistance, especially stress corrosion resistance, pitting corrosion resistance, crevice corrosion resistance, intergranular corrosion resistance, corrosion fatigue resistance and wear resistance.

2. Good weldability

When welding this kind of steel, the crack tendency is very low, and preheating and post weld heat treatment are not required. Due to the high content of N in the base metal, the single-phase ferrite zone will not be formed in the weld near the seam, and the austenite content is generally not less than 30%. Applicable welding methods include argon tungsten arc welding and electrode arc welding. Generally, in order to prevent grain coarsening in the near seam area, low linear energy welding shall be used as far as possible.

3. Good comprehensive mechanical properties

It has high strength and fatigue strength, and the yield strength is twice that of 18-8 austenitic stainless steel. The elongation of solid solution can be up to more than 40%.

If you have any interest, Please kindly feel free to contact me. THANKS !!!