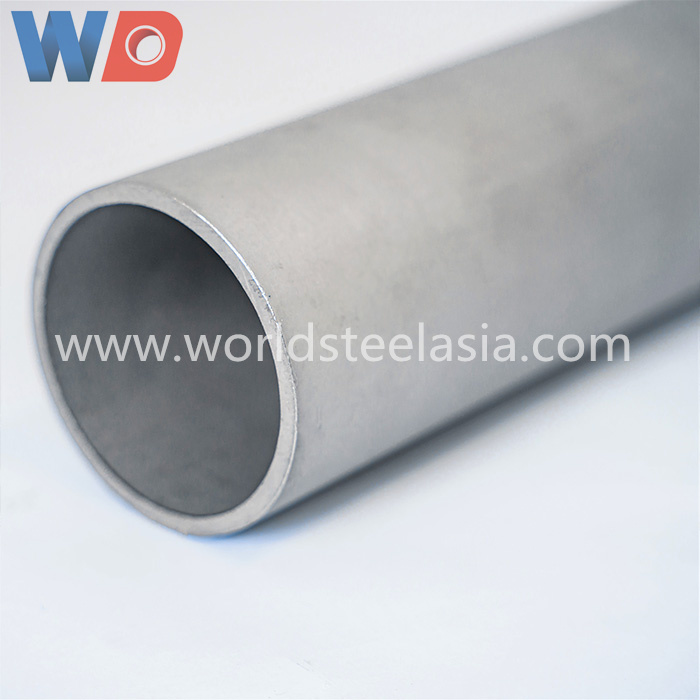

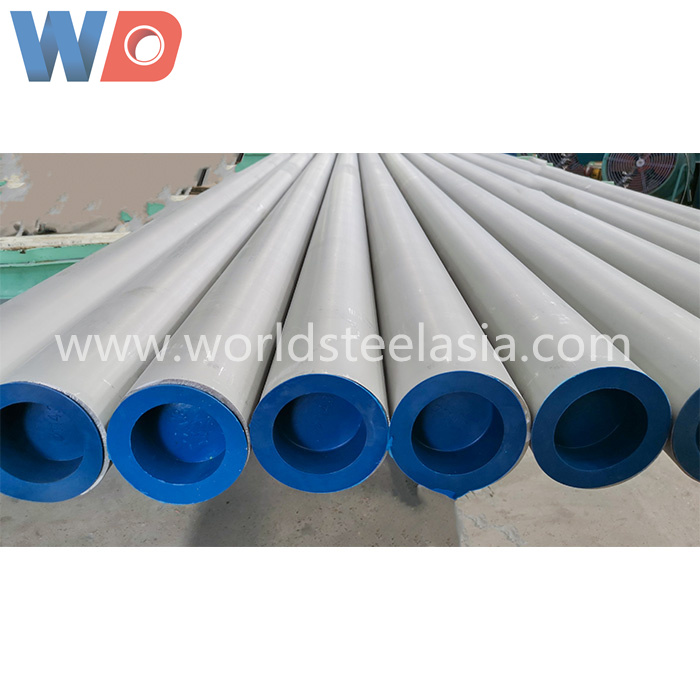

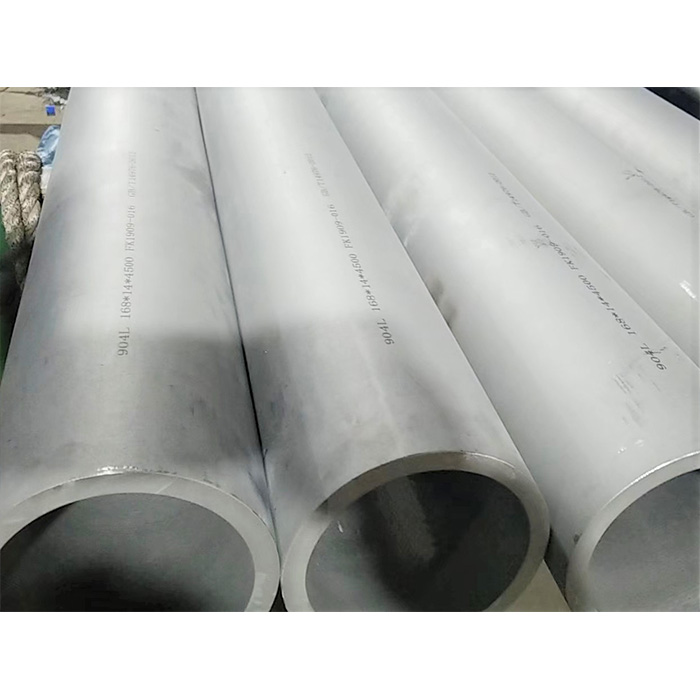

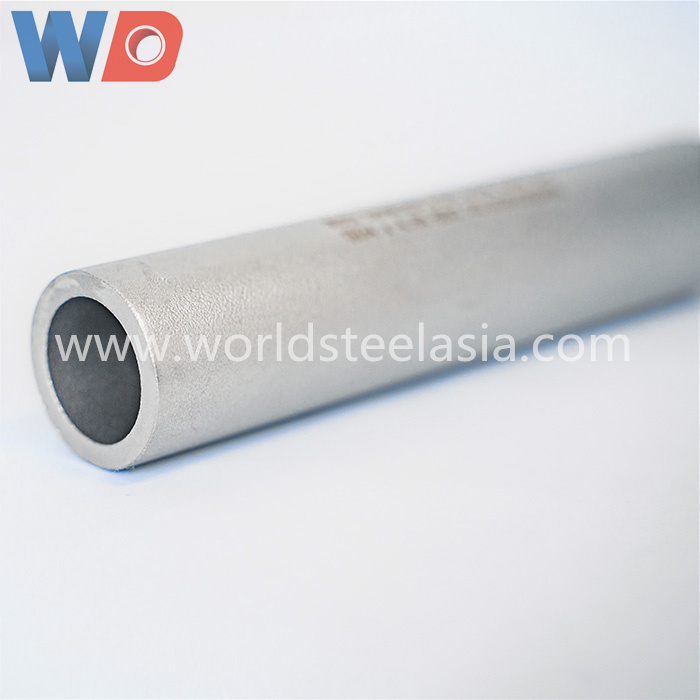

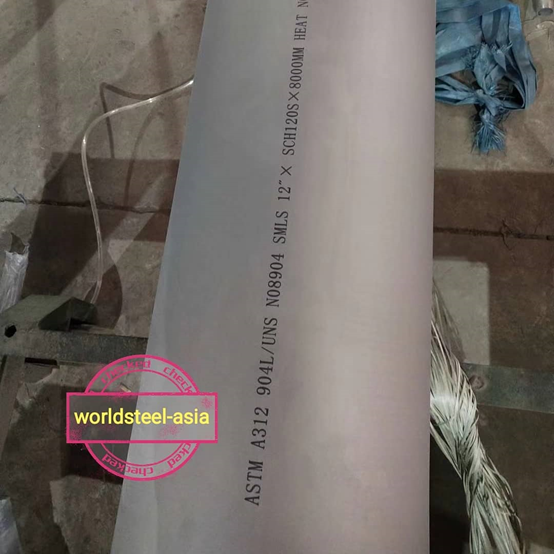

N08904 904L EN 1.4539 Seamless Pipe and pipe

Super austenite 904 (N08904) stainless steel pipe is a high alloy austenitic product intended for use under severely corrosive conditions. It offers good resistance to:

-Pitting and crevice corrosion

-Intergranular corrosion

-Stress corrosion cracking

-General corrosion

Application scope application fields include: 904L alloy is a multi-purpose material, which can be used in many industrial fields:

1. Petroleum and petrochemical equipment, such as reactors in petrochemical equipment.

2. Storage and transportation equipment of sulfuric acid, such as heat exchanger, etc.

3. The flue gas desulfurization device of power plant is mainly used in: tower body, flue, door baffle, internals, spray system, etc. of absorption tower.

4. Scrubber and fan in organic acid treatment system.

Aaustenite 904 & 904L ( UNS N08904 ) EN 1.4539 stainless steel pipe,904L fittings and 904L flanges are used in the chemical industry to process corrosive chemicals such as: Acetic acid, Acetylene, Acrylates, Acrylonitrile, Aluminum sulfate, Ammonium phosphate, Ammonium sulfate, Battery acid, Benzene, Butyl acetate, Caprolactum, Cellophane, Citric acid, Nitrophosphate, Oxalic acid, Superphosphate, Tall oil, Tartaric acid, Uranium oxide and Zinc sulfate.

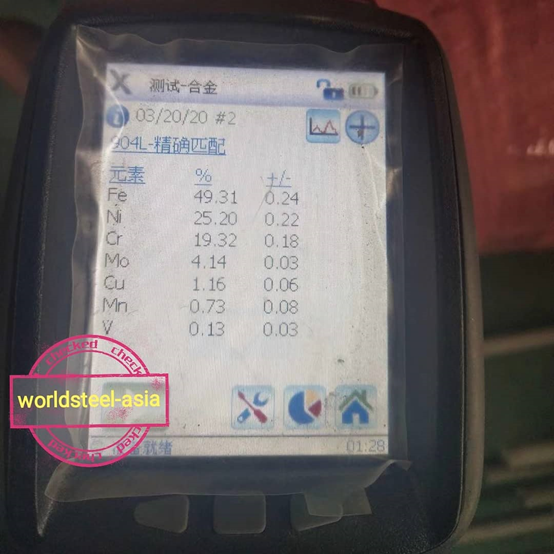

| CHONGQING WORLD STEEL CO.,LTD 904 & 904L ( UNS N08904 ) Chemical Requirements | |||||||||||

| Grade | UNS Desig- nationA | Composition, %B | |||||||||

| Carbon | Manga- nese | Phos- phorus | Sulfur | Silicon | Chrom- ium | Nickel | Molyb- denum | Nitro- genC | Copper | ||

| 904L | N08904 | 0.020 | 2.00 | 0.040 | 0.030 | 1.00 | 19.0 – 23.0 | 23.0 – 28.0 | 4.0 – 5.0 | 0.10 | 1.00 – 2.00 |

| 904L Minimum mechanical properties at room temperature: | |||

| Grade | Tensile Strength | Yield Strength | Elongation |

| Rm N/mm2 | RP0.2N/mm2 | % | |

| UNS N08904 / 904L | 490 | 216 | 35 |

Metallographic structure

904L Stainless steel pipe and fittings is a completely austenitic structure. Compared with austenitic stainless steel with high molybdenum content, 904L Stainless Steel has no effect on ferrite and α The precipitation of phase is not sensitive.

Super austenite 904L stainless steel seamless pipe is a non-stabilized austenitic stainless steel with low carbon content. 904L stainless steel pipe high alloy stainless steel has added copper to improve its resistance to strong reducing acids, such as sulphuric acid. The steel is also resistant to stress corrosion cracking and crevice corrosion. Super austenite 904L seamless stainless steel tube is non-magnetic, and offers excellent formability, toughness and weldability. Grade 904L ss pipe contains high amounts of expensive ingredients, such as molybdenum and nickel. Today, most of the applications that employ Super austenite 904L steel tube are replaced by low-cost duplex stainless steel pipe 2205.

Super austenite 904L seamless stainless steel pipe and fittings have excellent resistance to warm seawater and chloride attack. The high resistance of Super austenite 904L stainless steel flange against stress corrosion cracking is due to the presence of high amounts of nickel in its composition. Moreover, the addition of copper to these grades develops resistance to sulphuric acid and other reducing agents in both aggressive and mild conditions.

# N08904 / 904L main specifications:

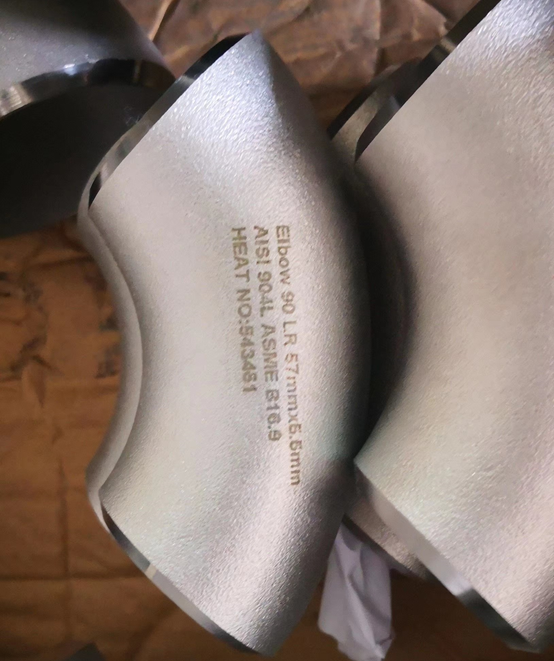

904L stainless steel welded tube N08904 seamless pipe, N08904 steel plate, N08904 round bar, N08904 forging, N08904 flange, N08904 ring, N08904 welded pipe, N08904 steel strip, N08904 straight bar, N08904 stainless steel tubpe, N08904 round cake, N08904 flat steel, 904L stainless steel pipe, N08904 904L concentric reducer, N08904 904L elbow 90 ° long radius, N08904 equal diameter tee and N08904 machined parts , 904L seamless stainless steel pipe

UNS N08904 / 904L stainless steel chemical composition

UNS N08904 / 904L mechanical properties

UNS N08904 / 904L: stainless steel pipe annealing temperature ?

UNS N08904 / 904L corrosion resistance

UNS N08904 / 904L intergranular corrosion