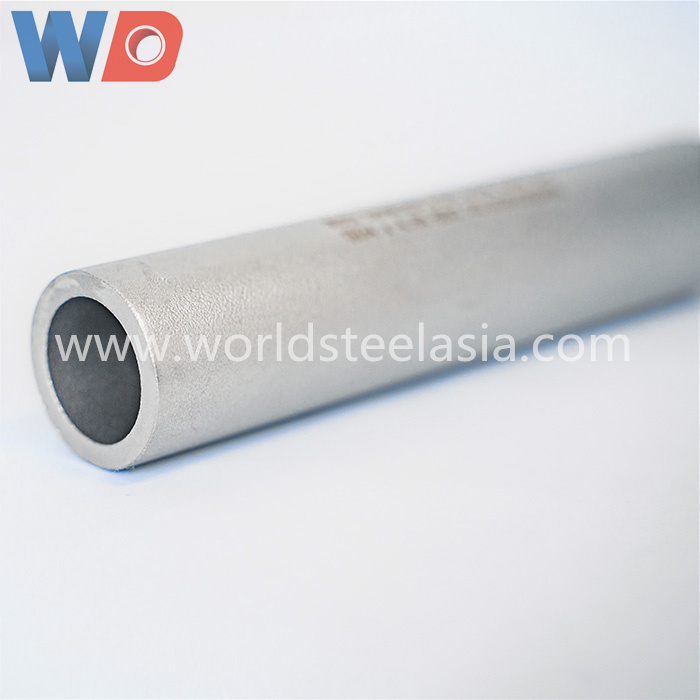

Heat Exchanger Bend Tubes and Pipe

ASTM A213 / A213M Heat Exchanger Bend Tubes Seamless Stainless Steel Tube

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. Grades containing the letter H in their designation have requirements different from those of similar grades not containing the letter H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. The tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade 304 316L shall be cold finished. Heat treatment shall be done separately and in addition to heating for hot forming. The ferritic alloy and ferritic stainless steels shall be reheated. On the other hand, austenitic stainless steel tubes shall be furnished in the heat-treated condition. Alternatively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution temperature, tubes may be individually quenched in water or rapidly cooled by other means. Tension test, hardness test, flattening test, and flaring test shall be done to each tube. Also, each tube shall be subjected to the nondestructive electric test or hydrostatic test.

Austenitic Stainless Steel - Boilers And Pressure Vessel Tubes - Ferritic Stainless Steel - Heat Exchangers - High-Temperature Services - Seamless Pipes And Tubes - Superheaters

Inspection And Yesting

Visual inspection shall be made on the clean pickled surface.

Testing shall include as follows:

Program | Testing |

- Heat analysis | 1/heat/size |

- Check analysis | 1/heat/size |

- PMI | 100% |

- Surface inspection | 100% |

- Dimensional check | 100% at the tube ends |

- Ecentricity check | 100% at the tube ends |

- Physical Test | As per Standard |

- Hardness | As per Standard |

- Hydrostatic Test | As per Purchase Order |

- Free from Mercury & Redioactive contamination | Shall be complied |

- Inclusion Test | 1/heat/size |

WORLDSTEEL Professional Team, Every Millimeter Is Exquisite

- Outer Diameter Inspection, Measuring 4 Points

- Wall Thickness Inspection, Measuring 4 Points

- Positive Material Identification ( 100% Per PC)

- Inside Diameter Inspection Per PC

Mill Test Certificate is supplied with shipment.

If needed, a Third Party Inspection is acceptable.

Why Us?

· Quality and Innovation

· Timely Deliveries

· Competitive Prices

· Excellent Customer Responsiveness

· Size can be customized to customer requirements chan

· Unending Pursuit of Product, Process and Performance Optimization

If you have any interest, Please kindly feel free to contact me. THANKS !!!