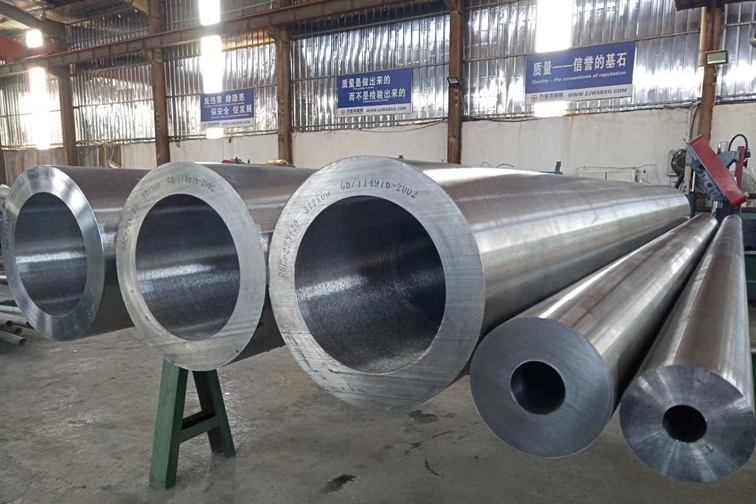

ASTM A511 Seamless Stainless Steel Hollow Tube

- WDSS

- MADE IN CHINA

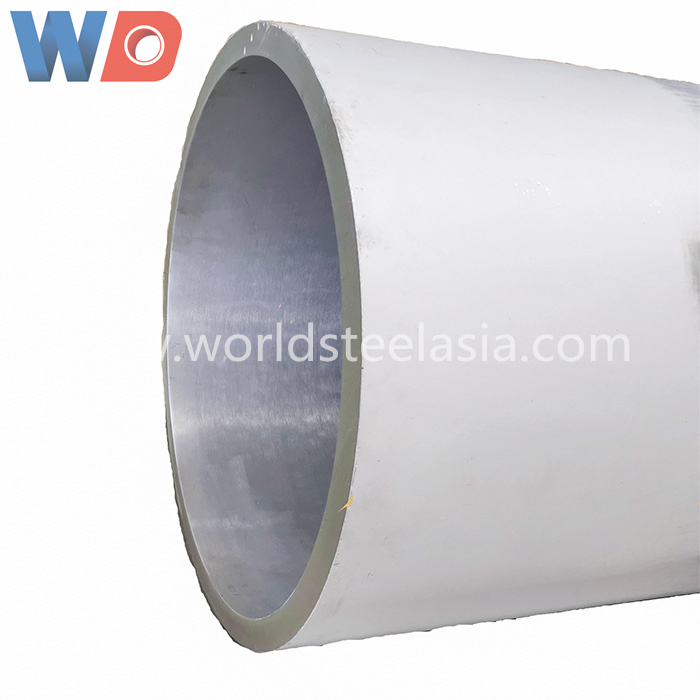

Heavy Wall Hollow Stainless Steel Seamless Tube

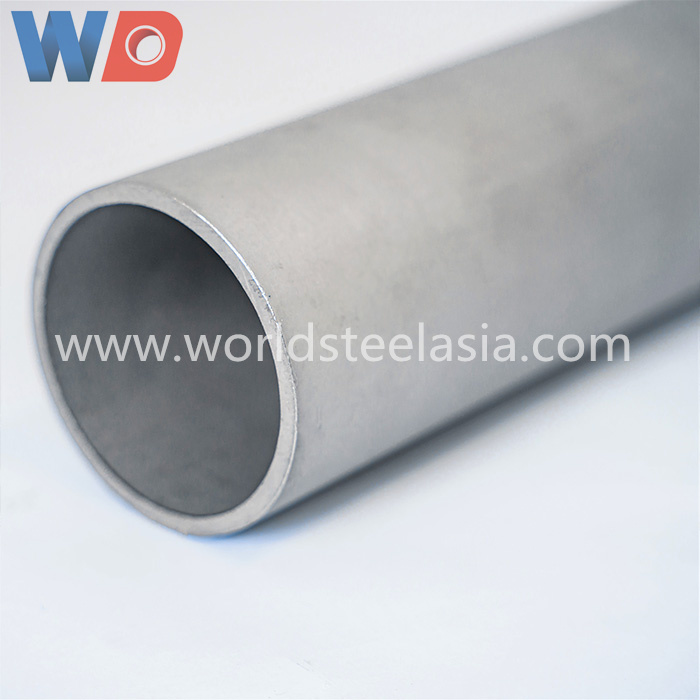

Thick wall hollow stainless steel seamless pipe is mainly used for lathe processing to other stainless steel products, such as threaded pipe joint, bearing pipe, casing, etc。

WORLDSTEEL To guarantee Stainless Steel Seamless Pipe meets certain standards, it has to be heat-treated in specific ways to ensure Stainless Steel Seamless Pipe the metallurgic properties are in accordance with the necessary requirements. This ensures extremely high quality and durability for our clients.

All Hollow Stainless Steel Seamless Tube are heat treated to facilitate lathe turning。

We work Raw materail manufactures with BAOSTEEL, TISCO, YONGXIN, WASIN, TSINGSHAN we can be confident in the products which we supply and know we can rely on their quality and performance.

Everything we supply is manufactured in accordance with the American Society for Testing & Materials (ASTM) Standards and the American Society of Mechanical Engineers (ASME)

Heavy Wall Hollow Stainless Steel Seamless Tube

Size range

Wall Thickness | 7mm-90mm, ANSI B36.19M/ B36.10: SCH10S SCH40S SCH80S SCH100 SCH120 SCH140 SCH160 SCHXXS, oter can be negotiated |

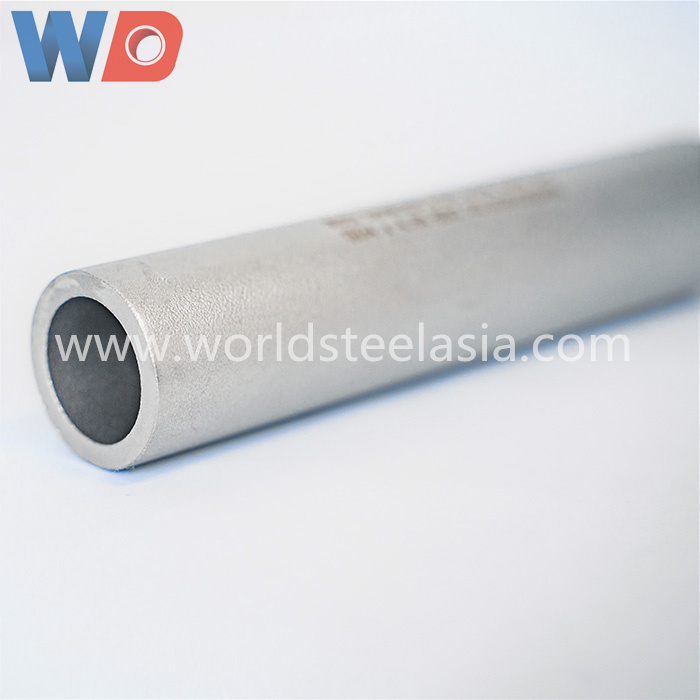

Out Diameter | 30mm-760mm, ASME B36.19M/ B36.10 |

Length | 1m, 3m, 6m, 12m, or as the customer's demand |

Surface Treatment | Pickling(No.1), Polished, Hair Line,Brush, Mirror Finish |

Manufacture Method | Cold Rolled, Cold Drawn, Extruded |

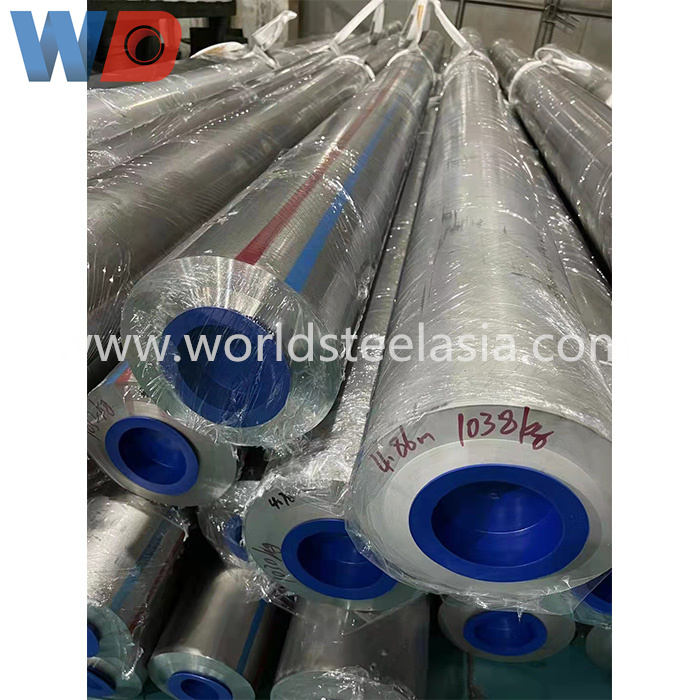

Package Type | Bundling, Woven Bags, PVC Film and Wooden Case |

Mill Test Certificate is supplied with shipment.

If needed, a Third Party Inspection is acceptable.

Application

1) For fluid & gas transport

2) Structure & machining etc

Advantages

1) Advanced technology of cold draw machine

2) Advanced annealing machine

3) Better mechanical property

4) More precise dimension

5) Perfect inspection method and inspection equipment etc

6) 100% PMI Test

Inspection break down:

Quantity, size and visual aspects of the products inspection: Making sure your product's surface, size and quality is aligned with the requirements ( good marking, proper packing), Mechanical and chemical testing.

Document completion: Testing report certificates and other documents which need to get completed before the products are sent from port.

If you have any interest, Please kindly feel free to contact me. THANKS !!!