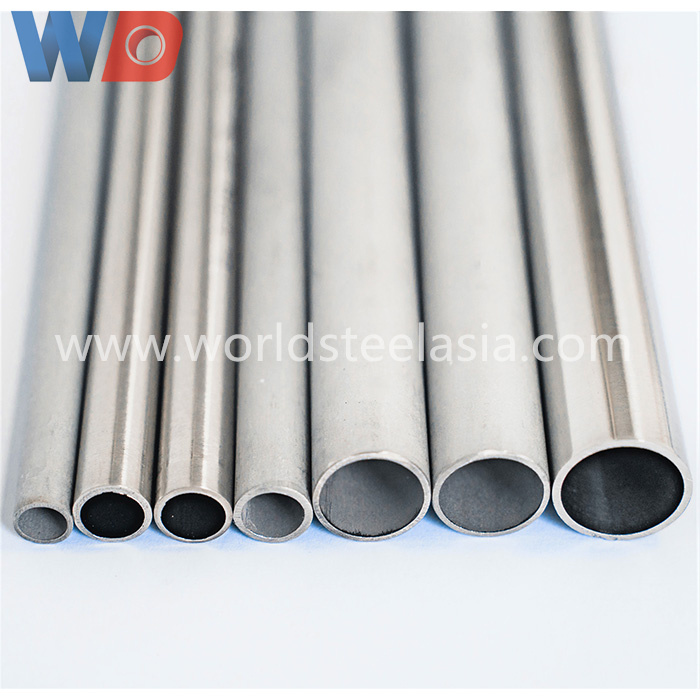

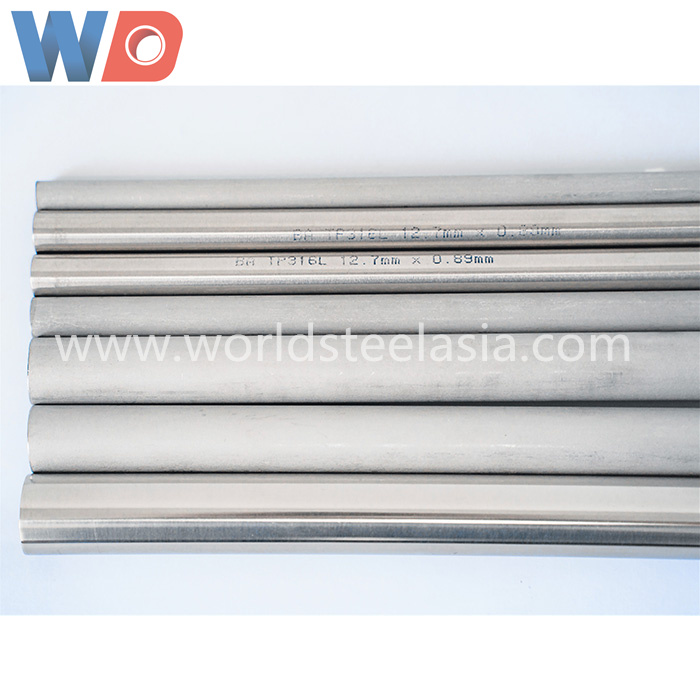

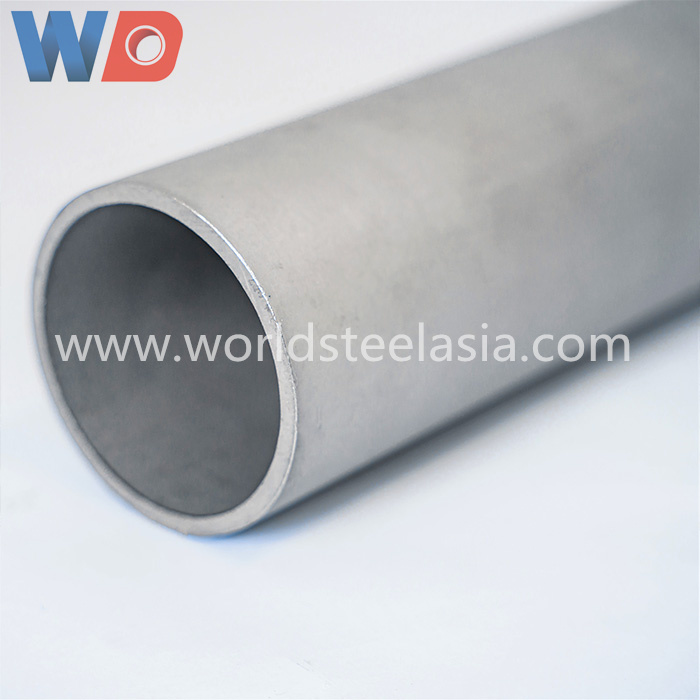

Hydraulic Systems Stainless Steel Tubular Annealing Pickling

ASTM A269 / A269M

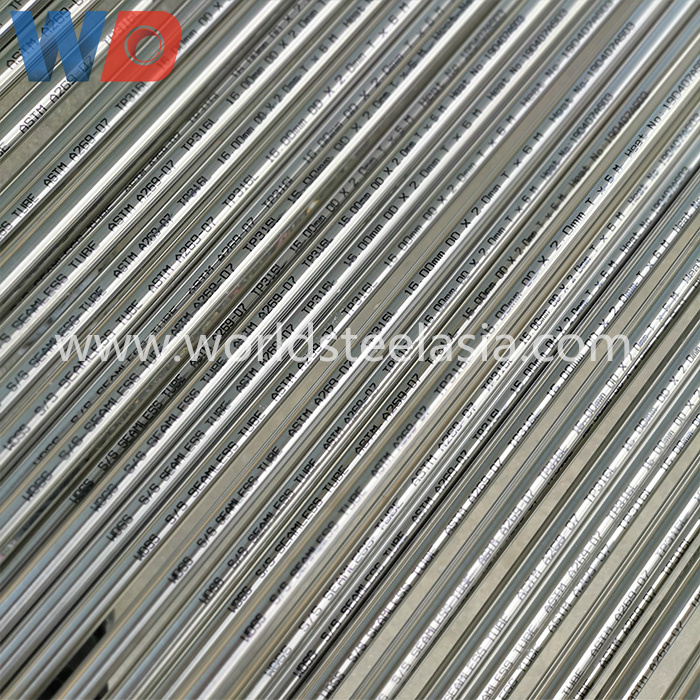

Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

This specification covers nominal-wall-thickness, seamless and welded austenitic steel tubing for general corrosion-resisting and low- or high-temperature service. All material shall be furnished in the heat-treated condition. The steel shall conform to the chemical composition requirements. Different mechanical test requirements that includes, flaring test, flange test, hardness test, and reverse flattening test are presented. Also, each tube shall be subjected to the non-destructive electric test or the hydrostatic test. Finally the hardness requirements for different grades of tubes are highlighted.

Austenitic Stainless Steel - Corrosive Service Applications - High-Temperature Service Applications - High-Temperature Services - Low-Temperature Services - Seamless Pipes And Tubes - Seamless Steel Tubes - Stainless Steel Tubes - Steel Tubes - Thickness - Pipes And Tubes - SS Seamless Steel Tubes

Austenitic Stainless Steel - Boilers And Pressure Vessel Tubes - Ferritic Stainless Steel - Heat Exchangers - High-Temperature Services - Seamless Pipes And Tubes - Superheaters

Inspection And Yesting

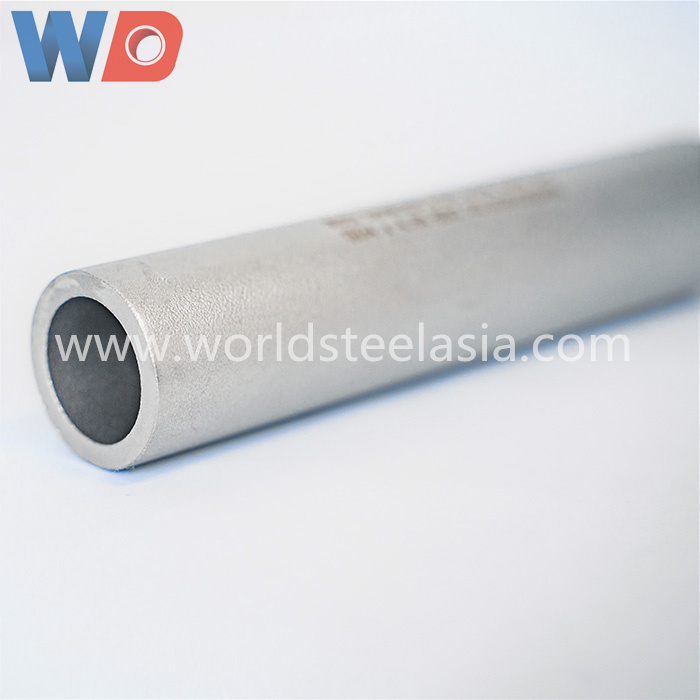

Visual inspection shall be made on the clean pickled surface.

Testing shall include as follows:

Program | Testing |

- Heat analysis | 1/heat/size |

- Check analysis | 1/heat/size |

- PMI | 100% |

- Surface inspection | 100% |

- Dimensional check | 100% at the tube ends |

- Ecentricity check | 100% at the tube ends |

- Physical Test | As per Standard |

- Hardness | As per Standard |

- Hydrostatic Test | As per Purchase Order |

- Free from Mercury & Redioactive contamination | Shall be complied |

- Inclusion Test | 1/heat/size |

WORLDSTEEL Professional Team, Every Millimeter Is Exquisite

- Outer Diameter Inspection, Measuring 4 Points

- Wall Thickness Inspection, Measuring 4 Points

- Positive Material Identification ( 100% Per PC)

- Inside Diameter Inspection Per PC

Mill Test Certificate is supplied with shipment.

If needed, a Third Party Inspection is acceptable.

Why Us?

· Quality and Innovation

· Timely Deliveries

· Competitive Prices

· Excellent Customer Responsiveness

· Size can be customized to customer requirements chan

· Unending Pursuit of Product, Process and Performance Optimization

If you have any interest, Please kindly feel free to contact me. THANKS !!!