Nickel Alloy Inconel 625 UNSN06625

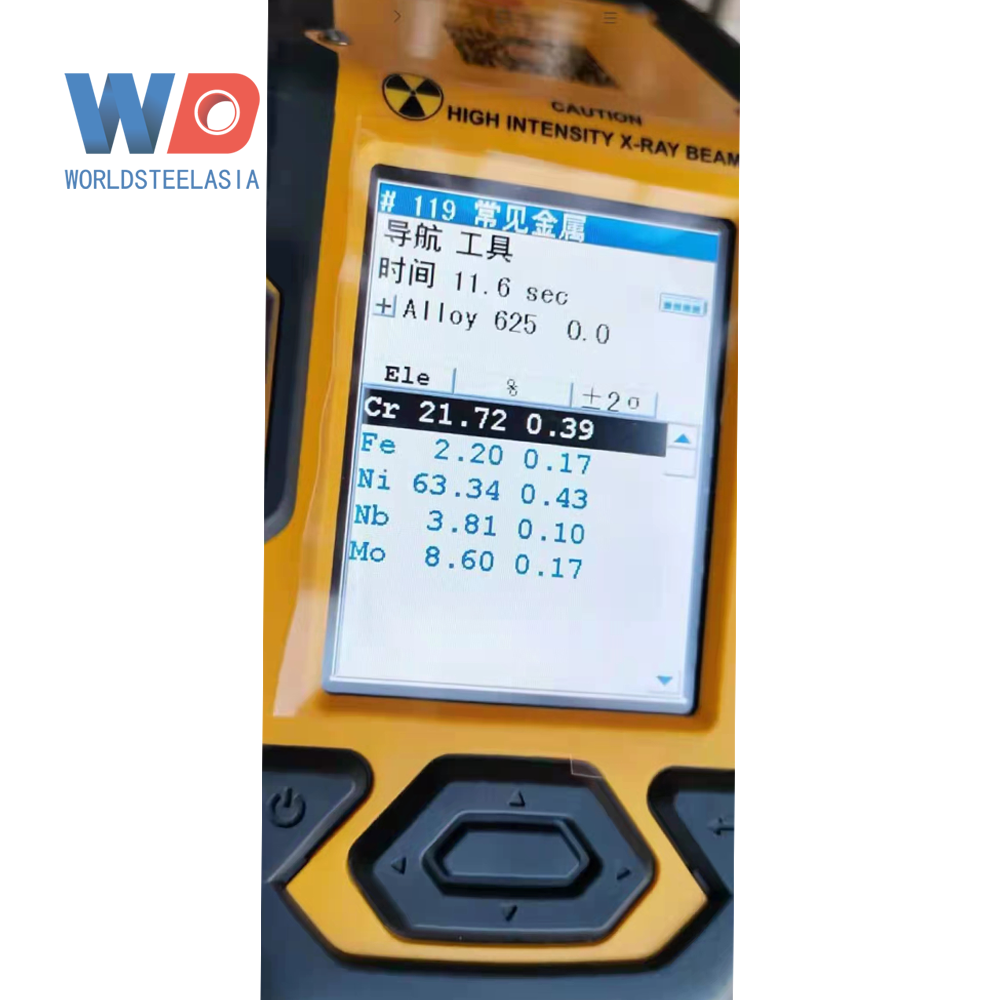

Inconel625 N06625 is a nickel chromium molybdenum niobium alloy with a pure austenitic structure in the solid solution state. Excellent strength at temperatures up to 1500 ° F (816 ° C) and resistance to various corrosive media. N06625 alloy has the advantages of high strength, good processability (including welding) and corrosion resistance. The operating temperature range is from low temperature to 1800 ° F (982 ° C). The strength of N06625 alloy comes from the strengthening effect of molybdenum and niobium on its nickel chromium matrix, so precipitation hardening treatment is not required. The alloy not only has good corrosion resistance, oxidation resistance and high strength, but also has good formability and toughness. It is applicable to the service conditions where both high corrosion resistance and high strength are required

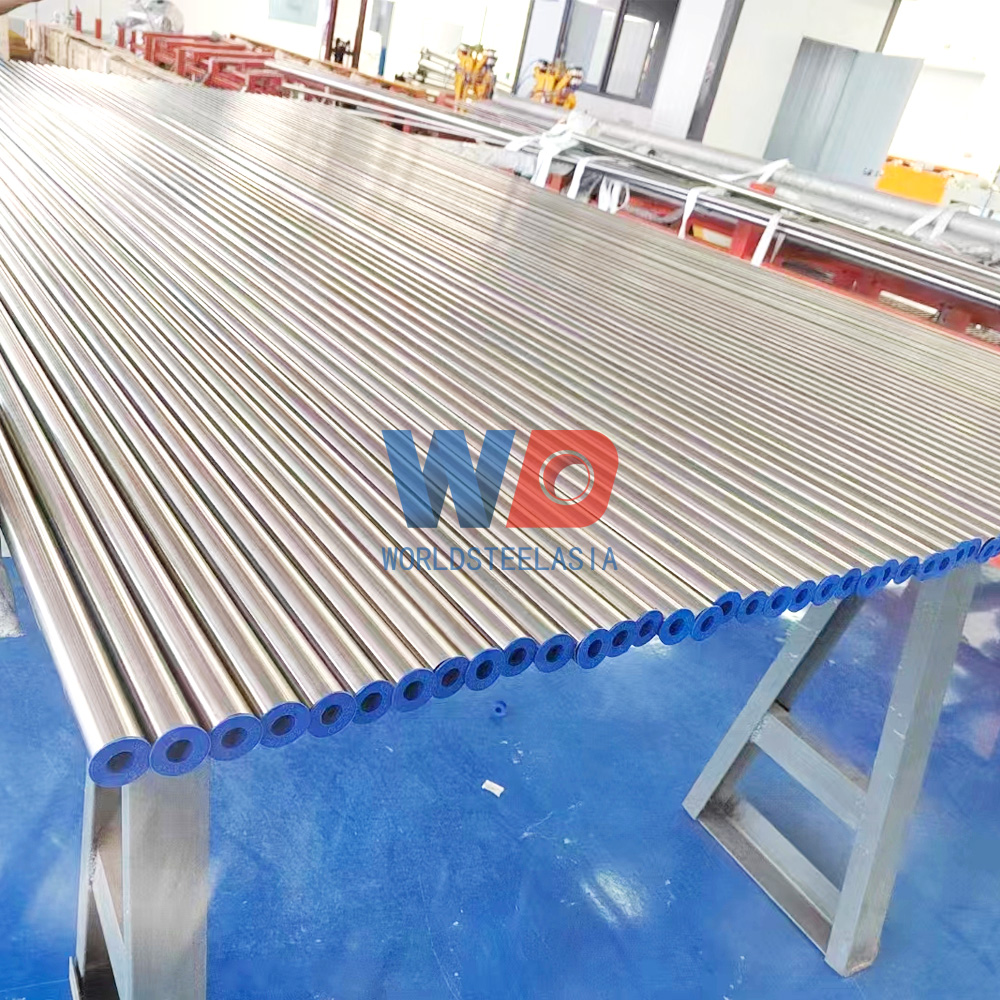

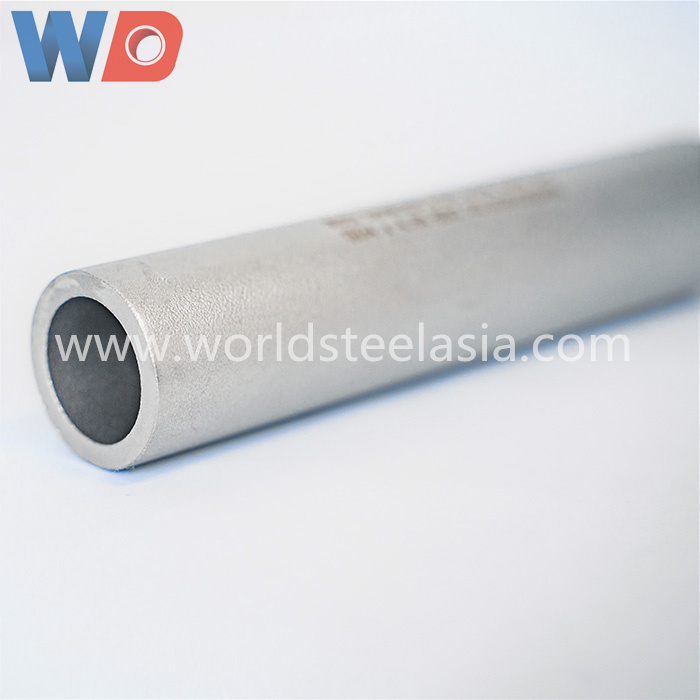

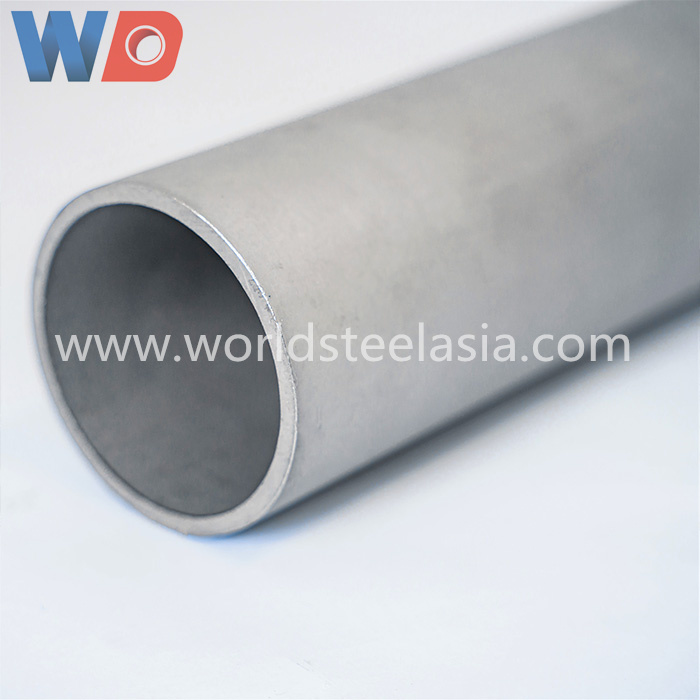

NICKEL BASE CORROSION RESISTANT ALLOY INCONEL 625 SEAMLESS PIPE & TUBE

Inconel625 N06625

American Standard: Inconel 625 UNS N06625

European standard: 2.4856/ NiCr22Mo9Nb

Chine standard: NS336 GH625 0Cr22Ni60Mo9Nb4

Japanese standard: NCF625

Inconel 625 products : Bar \ Plate \ Pipe & Tube ASME SB444 \ Flange \ Fittings.

Inconel 625 Chemical Composition

Inconel 625 Corrosion Resistance

In weak medium such as atmosphere, natural water, seawater, neutral salt and alkali, there is basically no obvious corrosion. In more severe medium, chromium can resist oxidizing acid and high-temperature oxidation due to its existence; It is nickel based and has high molybdenum content, so it is resistant to reducing acid medium. For local corrosion, high chromium and molybdenum content makes the alloy resistant to pitting and crevice corrosion, and high nickel and chromium content makes the alloy resistant to stress corrosion; The high content of Nb (Ti) makes the alloy not prone to intergranular corrosion. (1) Inconel625 N06625 Overall corrosion resistance a. The solid solution corrosion rate of this alloy is ≤ 0.75mm/a in nitric acid at 65% HNO3 and boiling temperature. (2) Inconel625 N06625 Local corrosion resistance a. The intergranular corrosion resistance has very good resistance to the sensitized intergranular corrosion. (3) Inconel625 N06625 Stress Corrosion The stress corrosion resistance is better than 718 alloy. (4) Inconel625 N06625 Corrosion fatigue According to the corrosion fatigue test results in seawater at room temperature, the corrosion fatigue strength of Inconel 625 alloy is obviously higher than that of Hastelloy C and Incoloy 800 and universal stainless steel 304 and 316ss. | |||||||||||||||

Inconel 625 Mechanical Properties

Inconel 625 alloy is suitable for use after cold and hot working and annealing when the general service temperature is ≤ 650 ℃; When the service temperature is higher than 650 ℃, it can be applied in the annealed or solid solution state. For high temperature creep or durability requirements, it is recommended to use in the solid solution state; The fine grain alloy is used at the temperature ≤ 816 ℃ and under the condition that the fatigue strength, hardness and instantaneous strength are required. After single aging at 732 ℃, the yield strength of this alloy is low (690~793MPa), while after double aging, the yield strength can be as high as 827~956MPa and still have high plasticity. When double aging, if the first aging temperature is increased from 718 ℃ to 746 ℃, the hardness of the alloy will also be improved. Inconel 625 alloy is subject to solution treatment at 746 ℃ × 8h furnace cooling+621 ℃ × After 8h air cooling double aging treatment and holding at 316 ℃ for 1000h, the tensile properties of the alloy have no obvious influence;

Inconel 625 Application Scope

Inconel 625 alloy It has both high corrosion resistance and good thermal strength, so it can be used as both corrosion resistant alloy and thermal strength alloy. In corrosion resistance applications, Inconel 625 alloy is mainly used as mixed acid resistant to HNO3, HNO3+H2SO4, HNO3+HF, wet phosphoric acid containing H2SO4, F -, Cl -, seawater corrosion resistance, etc; While the corrosion resistance of Inconel625 Plus alloy is similar to that of Inconel625 alloy in acid medium and seawater, it also has excellent chloride and sulfide stress corrosion resistance, pitting corrosion resistance, crevice corrosion resistance and other properties even in the aging state. Both alloys can be used as corrosion resistant and high-strength materials to manufacture towers, tanks, vessels, pipelines, reactors, heat exchangers, valves, etc.

Typical applications are as follows:

Phosphoric acid production equipment

A plant for the treatment of radioactive waste

Petroleum piping systems and bushings

Marine industry and seawater equipment

Seawater piping for shipbuilding

Stress corrosion cracking compensator

Heating furnace lining

Refinery and offshore platform combustion system

Thermal waste gas collector and compensator

from: www.worldsteelasia.com