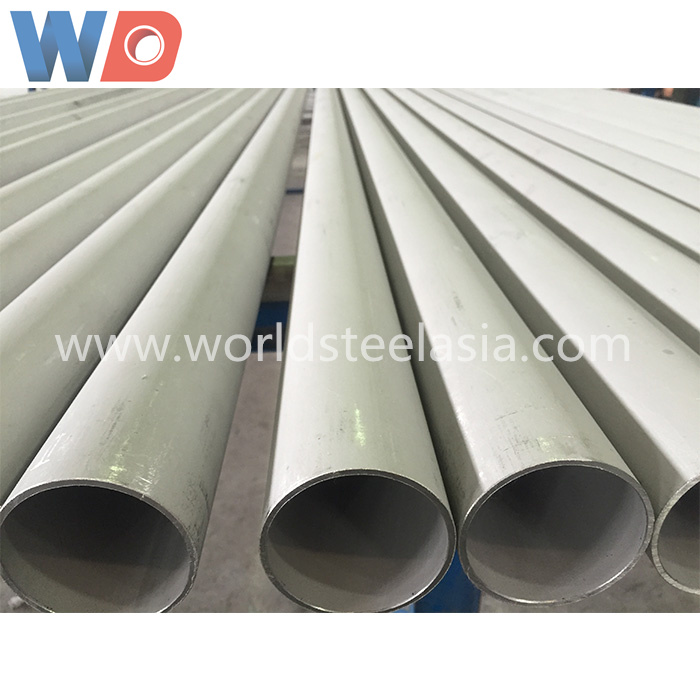

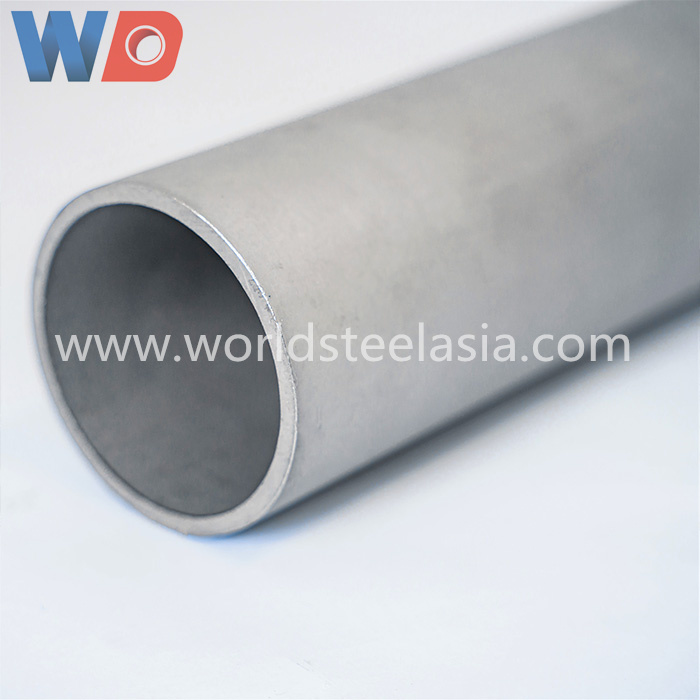

Nickel Base Alloys Seamless Pipe

Nickel based alloys have higher ability to accept soluble elements in solid solution than other stainless steel or iron-based alloys. Therefore, they can maintain high metallurgical stability. The combination of high alloying and multiple elements can provide good corrosion resistance in a wide range of environments, while still maintaining good welding and forming characteristics.

Nickel alloy is a good heat exchanger in chemical processing and nuclear industry. They are used in steam generator pipelines in the nuclear energy industry, high-temperature aircraft systems, and pipelines that need corrosion resistance, pressure resistance and temperature resistance in oil and gas production projects. Their corrosion resistance also makes them play a role in seawater desalination equipment.

Nickel base alloy pipe

Main material:

N04400, n06600, n06601, n06617, n06625, n06690, n08800, n08810, n08811, n08825, n08020, N08367, etc

Product details

1. Nickel base alloy is a kind of alloy with high strength and certain anti-oxidation and corrosion capacity at high temperature of 650 ~ 1000 ℃. According to the main properties, it is subdivided into nickel base heat-resistant alloy, nickel base corrosion-resistant alloy, nickel base wear-resistant alloy, nickel base precision alloy and nickel base shape memory alloy. According to the different matrix, superalloys are divided into iron-based superalloys, nickel based superalloys and cobalt based superalloys. Nickel base superalloy is called nickel base alloy for short.

2. Nickel base alloy is a very useful material for manufacturing high-quality pipe products. One of the key reasons is that they have excellent corrosion resistance in both water and high temperature applications.

3. In addition to high melting point, oxidation resistance and corrosion resistance, nickel alloy has good ductility. They can be electroplated and easy to weld. They are suitable for high and low temperature industrial occasions.

4. Nickel based alloys have higher ability to accept soluble elements in solid solution than other stainless steel or iron-based alloys. Therefore, they can maintain high metallurgical stability. The combination of high alloying and multiple elements can provide good corrosion resistance in a wide range of environments, while still maintaining good welding and forming characteristics.

Nickel alloy is a good heat exchanger in chemical processing and nuclear industry. They are used in steam generator pipelines in the nuclear energy industry, high-temperature aircraft systems, and pipelines that need corrosion resistance, pressure resistance and temperature resistance in oil and gas production projects. Their corrosion resistance also makes them play a role in seawater desalination equipment.

Product application

Nickel base alloys are used in many fields, such as:

1. Ocean: marine structure of marine environment, seawater desalination, mariculture, seawater heat exchange, etc.

2. Environmental protection: flue gas desulfurization device for thermal power generation, wastewater treatment, etc.

3. Energy field: atomic power generation, comprehensive utilization of coal, tidal power generation, etc.

4. Petrochemical Industry: oil refining, chemical equipment, etc.

5. Food field: salt making, soy sauce brewing, etc.

Performance characteristics (depending on the specific brand):

1. Good stress resistance, pitting corrosion resistance, crevice corrosion resistance and local corrosion resistance at room temperature Corrosion will hardly occur in medium environment, such as atmosphere, fresh water and seawater, neutral salts and alkaline medium. The combination of nickel and chromium can improve the corrosion resistance of oxidizing medium in more severe corrosive environment, and the combination of nickel and molybdenum provides the ability to resist non oxidizing medium environment.

2. Excellent mechanical properties Nickel base alloy has high tensile strength and good ductility at room temperature. Due to its unique microstructure, this characteristic can be maintained up to 850 degrees.

3. Shallow strain strength Shallow deformation is the phenomenon that the material slowly produces plastic deformation under the action of high temperature constant load, which is the reason for the failure of the material at high temperature. Among metal materials, nickel base alloys are widely used in various high temperature environments as load-bearing parts because of their best resistance to high temperature shallow deformation.

Common standards:

ASME SB163,ASME SB165,ASME SB167,ASME SB407,

ASME SB423,ASME SB444,ASME SB622,ASME SB668,

ASME sb690, ASEM sb729, etc.