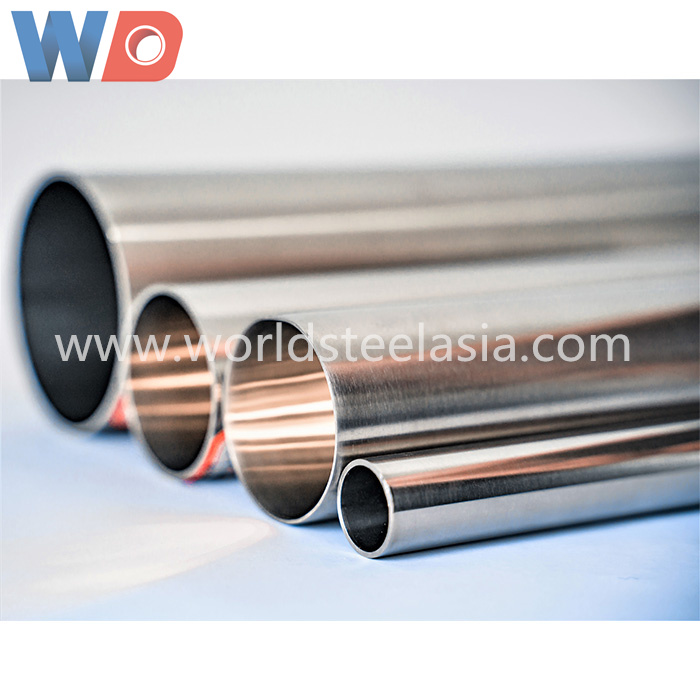

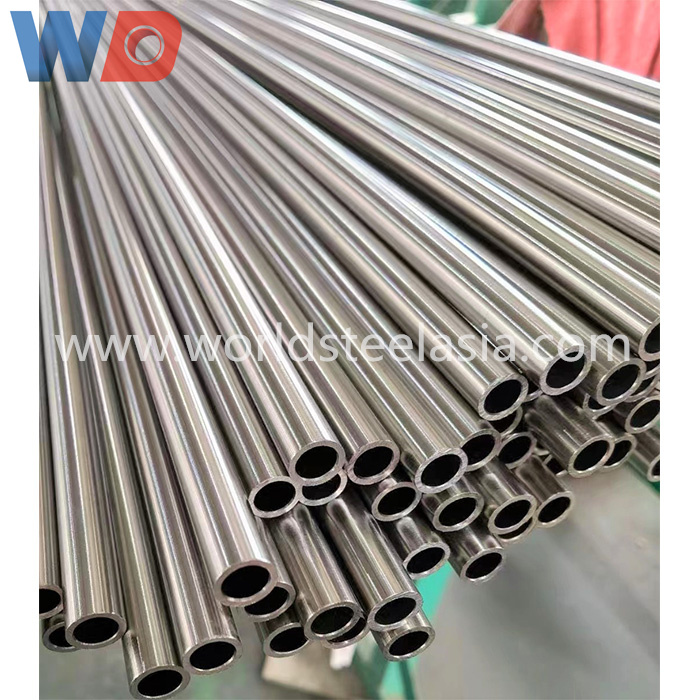

Polish Sanitary Stainless Steel Seamless Pipe

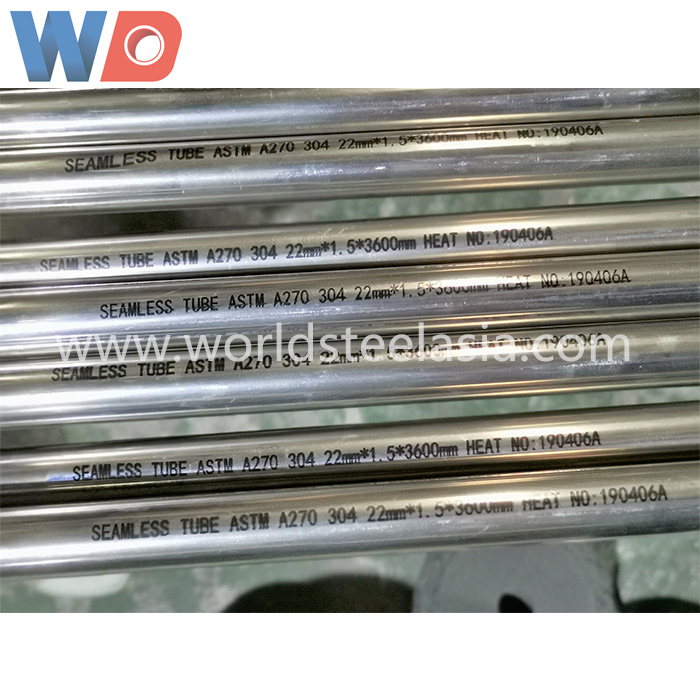

ASTM A270 / A270M

Standard Specification for Seamless and Welded Austenitic and Ferritic/Austenitic Stainless Steel Sanitary Tubing

This specification covers grades of seamless, welded, and heavily cold worked austenitic and ferritic/austenitic stainless steel sanitary tubing. Seamless tubes shall be manufactured by a process that does not involve welding at any stage. Welded tubes shall be made using an automated welding process with no addition of filler metal during the welding process. Heavily cold worked tubes shall be made by applying cold working of not less than 35% reduction of thickness of both wall and weld to a welded tube prior to the final anneal. No filler shall be used in making the weld. All material shall be furnished in the heat-treated condition. A chemical analysis of either one length of flat-rolled stock or one tube shall be made for each heat. Each tube shall be subjected to mechanical tests like reverse flattening test, hydrostatic test or nondestructive electric test. The following surface finishes may be specified: mill finish, mechanically polished surface finish, finish No. 80, finish No. 120, finish No. 180, finish No. 240, electropolished finish, and maximum roughness average surface finish. Longitudinally polished finish shall be performed on the inside surface only while a circumferential polished finish shall be done on either the inside surface, outside surface, or both.

This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

Keywords

Austenitic Stainless Steel - Cold Working - Duplex And Super Duplex Stainless Steel - Food Service Equipment - Food Servicing Equipment - Forming - Sanitary Pipes - Seamless Pipes And Tubes - Seamless Steel Tubes - Sewer Pipes - Welded Pipes And Tubes - Welded Steel Tubes

1. Application: stainless steel clean pipeline is used to transport high-purity or ultra pure gas in semiconductor industry and clean pipeline (all kinds of water) in biopharmaceutical industry.

2. Surface treatment method of Sanitary stainless steel pipeline system: AP (annealed & pickled): pickling passivation. After pickling passivation and cleaning, the internal surface of the pipeline will not improve the surface roughness, but can remove the residual particles and grease on the surface, reduce the energy level, but will not reduce the number of dielectric layers( PN2 / pH2) BA (bring annealed): bright annealing, high-temperature treatment in hydrogenation or vacuum state, on the one hand, eliminate internal stress, on the other hand, form a passivation film on the pipe surface to improve morphology and structure, reduce energy level and improve surface roughness to a certain extent( Discharge pipe of special gas and general nitrogen) Food Stainless Steel Pipe

EP (electro polished): chongqing world steel electrochemical polishing can greatly improve the surface morphology and structure and reduce the actual surface area to the greatest extent. The surface is a closed and thick chromium oxide film, the energy is close to the normal level of the alloy, and the number of media will be minimized( High purity and clean pipeline systems for transmission sensitive or corrosive media in microelectronics, optoelectronics, biological control and other industries generally use Ba and EP products.

3. Polish Stainless Steel Pipe material: grade 304 304L 316 316L 321 904L 347h 310S

( 316L pipe the most common in the industry, and its weldability, corrosion resistance and mechanical treatment performance are better than 304 304L 316 316L (1.4404) VOD (primary smelting ):

Low C: good welding performance and low hardness

Low S, P: good welding performance

Cr: good corrosion resistance...

316L stainless steel pipe VIM + var (remelting): low manganese material, corrosion resistance has been greatly improved. Other harmful substances are also lower.

4. Technical parameters to be considered for stainless steel pipeline

1) Product material and size manufacturing standard: ASTM A269 / a270 / A213, and other standards.

2) Chongqing worldsteel production environment: clean room level and process controllability and traceability.

3) Pressure: working pressure, explosion pressure (generally, the smaller the pipe diameter, the greater the pressure it bears)

4) Hardness: usually less than 80hrb (Rockwell hardness), which determines its mechanical properties

5) Tolerance: the allowable deviation range of product manufacturing, such as outer diameter, wall thickness, length, etc. generally, the international standard of wall thickness is + / - 10%. Dimension: the products provided by hiqua are inch standard (tube size), with specifications of 1 / 8 "~ 8"

6) Inner surface treatment process and its Ra value: RA is roughness average. It is generally believed that the smaller it is, the smoother its inner surface is. Product samples of surface treatment process of Chongqing worldsteel: 180 girt, 240 grid, 320 grid, 600 grid. The higher the grade, the smoother the surface.

7) Test means, methods and standards: their differences will also make the test results, which is also one of the factors affecting the comparability of products.

8) Product packaging: comply with international and factory standards. Generally, AP and Ba pipes are packed in single layer, EP is packed in double layer or wooden case.

9) Documentation: factory quality certificates and other delivery documents.